Handheld Laser Welder

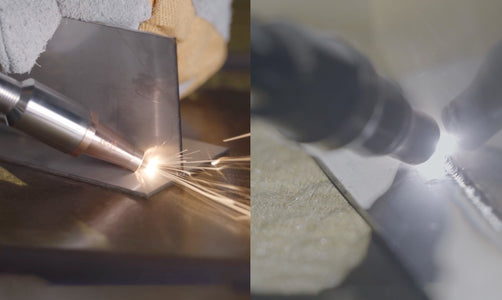

Three-in-One Function

Welding

- Heat affected zone is much smaller, so you can retain the materials’s natural properties much better, so it creates a much better weld

- Easy application as the filler will push the handle while welding, up to 4 times faster than traditional handheld welding processes(tig mig )

- Autogenous

Rust Removal

- Quickly remove rusty parts

- Use the scale tube to clean the welding seam with a width of 5 mm

Cutting

- Auxiliary cutting of metal materials.

- Laser welder can cut galvanized sheets, carbon steel, aluminum sheets and stainless steel materials with a thickness of 2 mm.

Screen-Equipped Welding Gun

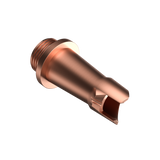

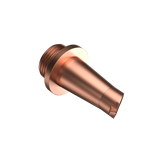

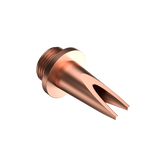

The handheld welding gun features a display screen for real-time monitoring and adjustment of welding parameters. 20 nozzles are included to cover any 0.8-1.2 mm wire welding, cutting, or cleaning needs. Additionally you can adjust the language of the display.

User-Friendly Controls

The intuitive touchscreen panel simplifies adjustments for air assist, laser, and wire feeding. The responsive welding gun throttle enables quick laser and wire discharge, ensuring a clean and efficient welding process without sticking.

1500W Powerful Laser Welding

OMTech's fiber laser welder uses a 1500W laser source to quickly and smoothly weld both thick and thin metals with minimal material deformation compared to traditional TIG or MIG welding.

Other Features

-

● The overall model is compact and lightweight, with three-sided handles on the top for easy movement.

● The main control screen of the welding machine can also control laser parameters and wire feeding parameters at the same time.

● The machine is equipped with a buzzer, which has low pressure alarm, high and low temperature alarm, self-protection and other functions. When necessary, the buzzer will sound an alarm and machine will stop emitting light;

● Equipped with a ground wire protection clip, the machine cannot emit light if it is not connected to the work platform.

-

● Equipped with an emergency stop button to stop work if necessary. Reliable safety guarantee is provided for operators.

● The whole machine is equipped with an air switch, which provides higher product safety and better usability.

● Install an oil-water separator to protect the focusing lens from oil and impurities, extending the service life of the product.

● The product machine comes with a one-year warranty and the laser has a two-year warranty.

Application

Case Show

Get A Free Demo

Fast and Easy Setup

Built-in Presets for Optimized Welds

Welding Steel, Aluminum, Copper, Titanium, Nickel Alloys

Cleaning Pre- and Post- Weld

Live Q&A

Get A Free Demo

Fast and Easy Setup

Built-in Presets for Optimized Welds

Welding Steel, Aluminum, Copper, Titanium, Nickel Alloys

Cleaning Pre- and Post- Weld

Live Q&A

Welding Capacity

|

Model

Material

|

BLW-1500 | |

| Stainless Steel |

Self-melting

Wire Filling

|

3 mm

4 mm

|

| Carbon Steel |

Self-melting

Wire Filling

|

3 mm

4 mm

|

| Aluminum Alloy |

Self-melting

Wire Filling

|

2 mm

2 mm

|

| Galvanized Sheet |

Self-melting

Wire Filling

|

3 mm

4 mm

|

| Titanium Alloy |

Self-melting

Wire Filling

|

3 mm

4 mm

|

Specs

| Laser Type | Fiber | Input Power | AC220 V, 60Hz |

|---|---|---|---|

| Max. Laser Power | 1500W | Cooling Type | Water Cooling |

| Operating Temperature | 5-45°C (41-113°F) | Operating Humidity | 10-90% |

| Max Continuous Operation Time | 24 hr. | Max. Working Parameter Storage | 50 + |

| Control System | HWS5000L | Max Seam Width | 0.06 in. (1.2 mm) |

| Max. Cutting Thickness (Cutting Mode) | depends on materials | Dimension | 38×22×38 in. (950×550×950 mm) |

| Max. Single-Side Welding Depth (Carbon Steel) | 0.16 in. (4 mm) | Max. Single-Side Welding Depth (Galvanized Plate) | 0.16 in. (4 mm) |

| Max. Single-Side Welding Depth (Aluminum Plate) | 0.08 in. (2 mm) | Max. Single-Side Welding Depth (Copper) | N/A |

| Max. Weld Width (Swing Width) | 0.06 in. (1.6 mm) | Laser Maximum Swing Width | 0.2 in. (5 mm) |

| Machine Input Power | 7000 W |

| Laser | |||

| Model | MFSC-1500w | Net Weight | 62+4 Ib. (28 ± 2 kg) |

|---|---|---|---|

| Dimension | 19×19×6 in.(483x478x128 mm) | Wavelength | 1080 ± 10 nm |

| Max. Input Power | 5000 W | Maxinum Output Power | 1500 W |

| Beam Parameters Product(BPP) | 1.5 | Fiber (Output Core Diameter) | 50 μm |

| Fiber (Length) | 394 in. (10 m) | Output Method | QBH |

| Modulation | 20 kHz | Energy Stability | <3% |

| Number of Output Beams | 1 | Cooling Medium | Distilled Water, Deionized Water |

| Wire Feeder | |||

| Speed | 0.6-24 in./min (15-600 mm/min) | Dimension | 21×10×18 in. (520×250×440 mm) |

|---|---|---|---|

| Wire Diameter | 0.8/1.0/1.2 mm | ||

| Lens | |||

| Focusing Lens Diameter | 0.79 in. (20 mm) | Focusing Lens Thickness | 0.08 in. (2 mm) |

|---|---|---|---|

| Focusing Lens Type | Zinc Selenide Lenses | Focusing Lens Focal Length | 5.9 in. (150 mm) |

| Collimating Lens Diameter | 0.79 in. (20 mm) | Collimating Lens Type | Zinc Selenide Lenses |

| Collimating Lens Thickness (Edge Thickness) | 0.1 in. (2.65 mm) | Collimating Lens Thickness (Maximum Thickness) | 0.2 in. (5 mm) |

| Reflector Diameter | 0.79 in. (20 mm) | Reflector Thickness | 0.1 in. (3 mm) |

| Reflector Type | Zinc Selenide Lenses | ||

FAQs

This advanced laser welding machine excels in producing durable and aesthetically pleasing welds while significantly reducing material deformation. Additionally, its user-friendly interface requires less technical expertise compared to conventional welding techniques, making it an efficient and accessible option for precise and high-quality welds.

Certainly. Safety is a top priority with this laser welding machine. It mandates grounding for fiber laser emission and incorporates multiple safety measures such as low-voltage protection, temperature alarms, emergency stops, and other safeguards to ensure a secure operating environment.

Here are some tips for maintaining your laser welding machine:

Regular cleaning: Clean the laser welding machine's exterior and work surface on a regular basis to remove dust, dirt, and debris.

Check the consumables: Replace the consumables of the laser welding machine, such as the focusing lens and mirrors, according to the manufacturer's recommendations.

Inspect the optics: Regularly inspect the laser welding machine's optics, including the laser head, mirrors, and beam path components.

Proper storage: When not in use, store the laser welding machine in a clean and dry environment away from direct sunlight and heat sources.

Material Compatibility: Commonly welded materials include steel, aluminum, stainless steel, titanium, and various alloys.

Surface Finish: A clean surface allows the laser beam to reflect off the material, creating a strong weld.

Workpiece Alignment: Alignment is crucial to ensure the laser beam hits the desired spot and the weld is formed correctly.

Joint Preparation: The joint area where the weld is to be formed should be prepared appropriately. Creating a V-shaped or U-shaped groove, and ensuring a good fit between the two workpieces.